Thin Film Laboratory

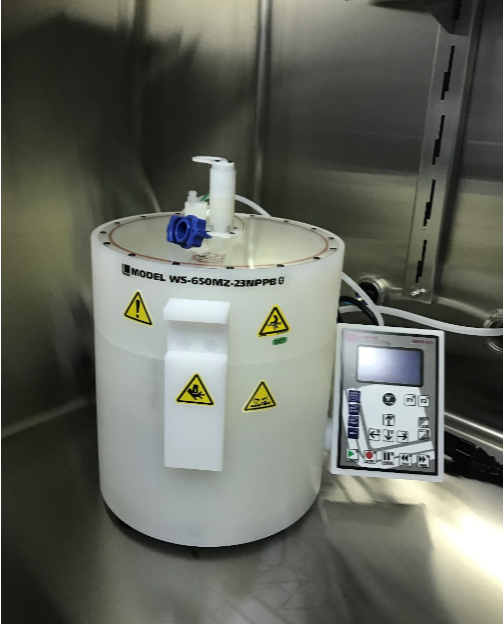

Spin Coater

Spin Coating or Spin Coating is a procedure used to apply thin films to flat sheets or substrates. Generally, a small amount of coating material is applied to the center of the substrate. The substrate is then rotated at high speed to disperse the coating material by centrifugal force.

The Laurell WS-650 series spin coater is compact and packed with advanced features. This 650-series coater system will accommodate up to ø150mm wafers and 5" × 5" (127mm × 127mm) substrates, and features a maximum rotational speed of 12,000 RPM (based on a ø100mm silicon wafer).

Dip Coater

In dip coating processes, the substrate is immersed in a liquid coating solution and then withdrawn from the solution at a given rate. Coating thickness generally increases with increasing retraction speed. The factors affecting the coating thickness are mainly fluid viscosity, fluid density and surface tension.

Travelling distance: 0-200 mm adjustable

Working temperature is up to 200°C from ambient

Programmable with accuracy within +/- 0.02%

Dwelling time: 1-999 seconds

GloveBox

Gloveboxes made of stainless steel provide a working environment for materials science, chemistry, semiconductor and similar fields. The glovebox system is a complete full size stand alone glovebox. It is capable of achieving and maintaining a less than 1 ppm H2O and O2 inert gas environment.

Türkçe

Türkçe